| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 5-7 Days |

Model No.: HS-1831

Coal Mine industry Type Conveyor Belt Return Roller

Roller is an important part of the belt conveyor,bear more than 70% of the resistance. Roller's role is to support the conveyor belt and the weight of the material. Roller must be flexible and reliable operation,reduce the friction with roller conveyor belt. Therefore, the quality of the roller is particularly important.Ultra-high molecular weight polyethylene (UHMWPE) the supporting roller is a new generation of plastic instead of steel of high-tech products,molecular weight polyethylene pipe material, plastic, metal, bearings, metal shaft bearing and seal assembly and become a hi-tech product.

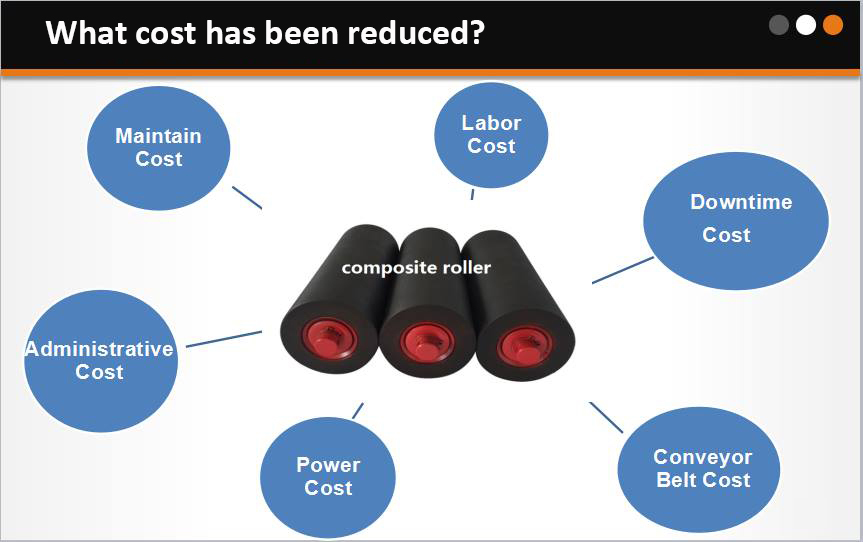

Composite rollers Advantages

1. The shell is Composite material.

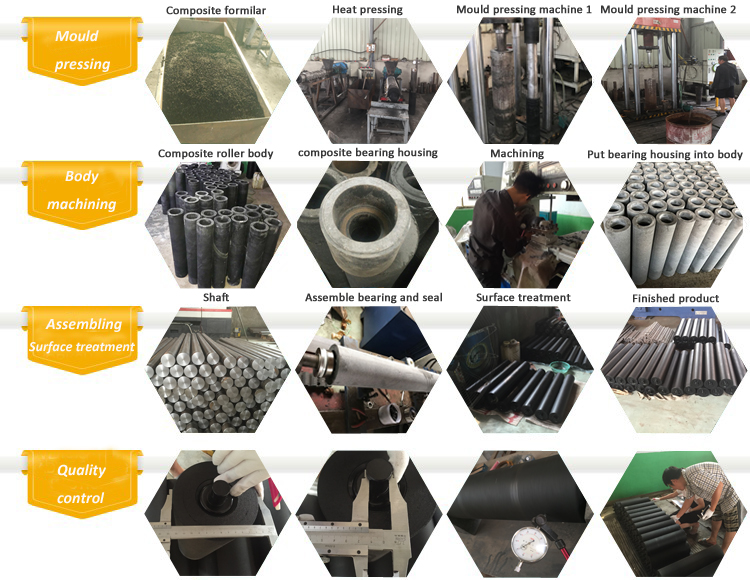

2. Composite roller is made of composite shell,composite bearings seat, metal shaft, bearings and DTII type seals.

3. The roller and bearing seat are processed by special double end boring machining. The machine adopts double cutter,double system control, single knife adjustment. A clamping and cutting independent ends. Non tolerance tight fit assembly of roller body and bearing seat. The processing concentricity is less than 0.02mm.

4. Conveyor roller dia (mm): 89,108,121,127,133,152,159,178,219

Roller length 160-2800mm

Shell thickness mm 15.0-30.0mm

5. Composite conveyor rollers working life is 8-10 times longer than steel rollers.

6. Super long wear resistance life

7. Anti corrosion, anti acid and alkali

8. Anti dust adhesion, protect conveyor belt

9. TIR less than 0.1mm, lower noise

10. High anti magnetic

What can we offer?

We mainly provide Belt Conveyor systems and Belt conveyor parts:

1. Conveyor Rollers/conveyor idlers: Return Roller, Carrying Roller, Chip conveyor, Impact roller, Buffer Roller, Adjusting Roller, Garland Roller, Cleaning Roller, Troughing Roller and Spiral Roller.

Conveyor roller material: Composite conveyor roller, steel roller, HDPE roller, UHMWPE roller, Plastic roller, rubber coated roller, CNC chip conveyor.

2. Conveyor Belts: Flat Rubber Belt, Steel Cord Rubber Belt, Pattern Conveyor Belt, Sidewall Rubber Belt, Machine Bellows Cover, Steel Telescopic Cover, etc.

3. Conveyor Pulleys / conveyor Drums

4. Conveyor Idler roller frames / Conveyor roller brackets.

5. All kinds bearings with different brands.

Why Choose Us

1. With 30 years experience of hydraulic components in china.

2. Best manufacturing machinery, quality level, best price, best service.

3. We have very good and comprehensive after-sales service.

4. We have no MOQ for clients and tailor made to clients request for our huge inventory.

Our Service

Pre-sale service: we provide pre-sale in our first cooperation make clear your situation and give you some advice.

In-sale Service: We will track the production progress and quality, check the exact model and quantity one by one before delivering.

After-sale Service: We will provide a one year free warranty and lifetime maintenance. We will change all questions in 7*24hours if you buy from us.

FAQ

Question 1: Did you accept products customization? Do they need mould fee?

Answer: Yes, we accept products customization. Need mould fee, because products usually need extra mould cost. But we can return the mould fee when order reach a specific quantity.

Question 2: Can we get free samples?

Answer: The sample expense and freight expense will be borne by the buyers, and will be returned in the following orders.

Question 3: How long is normal production period for a 20-foot shipping container?

Answer: Accoring to the current productive capacity, usually need 3-14 days from producing to delivery. (not including customized products)

Question 4: What is the type of payment?

Answer: Usually, you should prepay 50% of the total amount. The balance should be paid before delivery. (We'll send photos of product to you for checking before delivery)

Question 5: How to guarantee the high quality?

Answer: We have testing department to make sure quality of every product, appearance and pressure test are good.

Product Categories : Conveyor System > Quartz Conveyor Roller